- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

Mulite

Description

Our company's mullite products include naturally sintered mullite, synthetic sintered mullite, fused mullite and fused zirconium mullite,widely used in iron and steel metallurgy, foundry, building materials, non-ferrous metal smelting, refractories and other industries,with its stable quality and performance, has achieved good results, has been the domestic and foreign customers alike.welcome to know and negotiate, we will achieve your satisfaction with excellent quality and service.

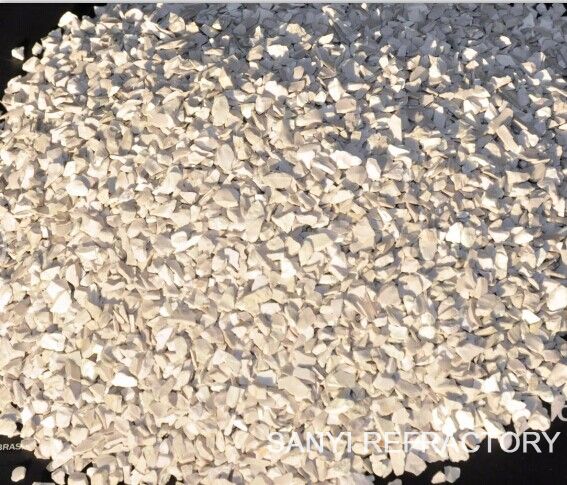

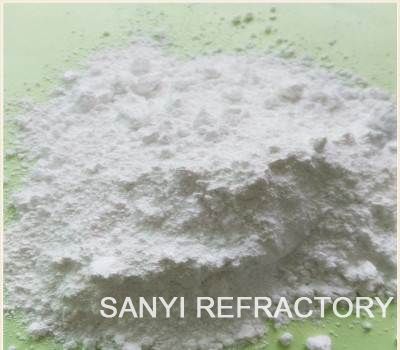

Natural sintered mullite is made from pure natural quality kaolin ore calcined in natural gas shaft furnace at high temperature. It has the advantages of high whiteness, low impurity content, high volume density, good fire resistance, etc.Naturally sintered mullite sand is an ideal material for precision casting, It can make castings easy to release mold, no deformation, not easy to scale, good finish, high yield.It is also used as a low alumina mullite brick, insulating brick, refractory castable and other refractory products. It can effectively reduce the porosity of products and improve thermal shock stability. It is an ideal refractory raw material.

Specification :

Natural sintered mullite is made from pure natural quality kaolin ore calcined in natural gas shaft furnace at high temperature. It has the advantages of high whiteness, low impurity content, high volume density, good fire resistance, etc.Naturally sintered mullite sand is an ideal material for precision casting, It can make castings easy to release mold, no deformation, not easy to scale, good finish, high yield.It is also used as a low alumina mullite brick, insulating brick, refractory castable and other refractory products. It can effectively reduce the porosity of products and improve thermal shock stability. It is an ideal refractory raw material.

Specification :

| Natural Sintered Mullite | ||

| Item | M47 | |

| Chemical Content | Al2O3,% | 45-47 |

| SiO2,% | 51-53 | |

| Fe2O3,≤% | 0.8 | |

| TiO2,≤% | 1.21 | |

| K2O+Na2O,≤% | 0.1 | |

| CaO+MgO,≤% | 0.2 | |

| Physical Properties | B.D, ≥g/cm3 | 2.5 |

| Refractorinesss, ≥% | 1760 | |

| Mullite Phase,% | 60-65 | |

Size Available :

Sized Sand: 0-1mm, 1-3mm, 3-5 mm,5-8mm,8-12mm

Fine Powders: 100mesh, 180mesh,240mesh,320mesh

In addition to supply in accordance with the above standards, we can also according to your request for granularity processing.

Leave a message: Please fill in your information and we will contact you soon.