- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

Fluorite

Description

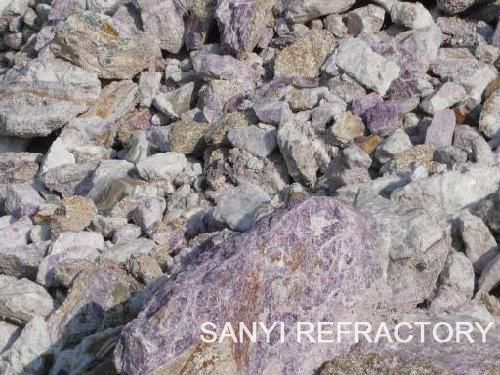

Fluorite is widely used in metallurgical, chemical and building materials industries, followed by light industry, optics, sculpture and defense industries. According to the application requirements, there are mainly four series of fluorite products in China, namely, fluorite lump, fluorite concentrate, fluorite powder and optically carved fluorite.

In metallurgical industry, fluorite, as an important flux for smelting, can effectively reduce the melting point of refractory substance in slag, promote slag flow, make slag and metal separate well, at the same time, it has the function of desulphurization and dephosphorization. Enhance metal forgability and tensile strength and other characteristics. Therefore, it is widely used in iron and steel smelting, ferroalloy production, iron technology and non-ferrous metal smelting. For smelting fluorite, the content of calcium fluoride is generally higher than 65%, and the main impurity SiO2 is required to some extent. The content of sulfur and phosphorus is strictly restricted, and the content of sulfur and phosphorus should not be higher than 0.3% and 0.8%, respectively.

Fluorite is the main raw material for hydrofluoric acid production in the chemical industry.Hydrofluoric acid is produced by the reaction of acid fluorite (fluorite concentrate) with sulfuric acid in a heating furnace. Hydrofluoric acid is divided into anhydrous hydrofluoric acid and aqueous hydrofluoric acid, which are colorless liquids that are volatile, have a strong irritating smell and are strongly corrosive. They are the key raw materials for the production of organic and inorganic fluorides and fluorine, It is also widely used in aluminum, aerospace, atomic energy, medicine and other industries.The chemical industry has high quality requirements for fluorite products. Generally, the content of CaF2 should be in the range of 93-98%. Silica and calcium carbonate are harmful impurities, which should be strictly restricted.

In the building material industry , the fluorite is widely used in building materials such as glass , ceramics , cement and the like . In the glass industry , the fluorite is added as a fluxing agent and a shading agent , which can promote the melting of the glass raw material , and the addition amount is between 1 and 3 percent when used as a fluxing agent , and the addition amount is 10 to 20 percent when used as a shading agent , The quality requirements of fluorite in glass industry are strict and the content of CaF2 is higher than 80% Fe2O3 is less than 0.2%.

In cement industry, the addition of fluorite as mineralizer can reduce sintering temperature and fuel consumption, increase the liquid viscosity of clinker and promote the formation of tricalcium silicate. In cement production, the amount of fluorite is between 0.8% and 5%. Although the quality requirement of fluorite in cement industry is not strict, the general CaF2 content can be more than 40%, and the impurity content is not specified.

In ceramic industry, fluorite is mainly used as porcelain glaze, which can help color and melt in the production process of porcelain glaze. The amount of fluorite added in the production of porcelain glaze is about 10 to 20 percent. Fluorite is also used in enamel industry and cast stone production, the addition amount is 3-10% and 3% respectively.

In refractory industry, fluorite powder as a mineralizer, especially in the production of siliceous refractory brick, adding a certain proportion of fluorite powder can effectively reduce the surface cracks of products, eliminate the appearance defects, and improve the yield of finished products.

SPECIFICATION :

In metallurgical industry, fluorite, as an important flux for smelting, can effectively reduce the melting point of refractory substance in slag, promote slag flow, make slag and metal separate well, at the same time, it has the function of desulphurization and dephosphorization. Enhance metal forgability and tensile strength and other characteristics. Therefore, it is widely used in iron and steel smelting, ferroalloy production, iron technology and non-ferrous metal smelting. For smelting fluorite, the content of calcium fluoride is generally higher than 65%, and the main impurity SiO2 is required to some extent. The content of sulfur and phosphorus is strictly restricted, and the content of sulfur and phosphorus should not be higher than 0.3% and 0.8%, respectively.

Fluorite is the main raw material for hydrofluoric acid production in the chemical industry.Hydrofluoric acid is produced by the reaction of acid fluorite (fluorite concentrate) with sulfuric acid in a heating furnace. Hydrofluoric acid is divided into anhydrous hydrofluoric acid and aqueous hydrofluoric acid, which are colorless liquids that are volatile, have a strong irritating smell and are strongly corrosive. They are the key raw materials for the production of organic and inorganic fluorides and fluorine, It is also widely used in aluminum, aerospace, atomic energy, medicine and other industries.The chemical industry has high quality requirements for fluorite products. Generally, the content of CaF2 should be in the range of 93-98%. Silica and calcium carbonate are harmful impurities, which should be strictly restricted.

In the building material industry , the fluorite is widely used in building materials such as glass , ceramics , cement and the like . In the glass industry , the fluorite is added as a fluxing agent and a shading agent , which can promote the melting of the glass raw material , and the addition amount is between 1 and 3 percent when used as a fluxing agent , and the addition amount is 10 to 20 percent when used as a shading agent , The quality requirements of fluorite in glass industry are strict and the content of CaF2 is higher than 80% Fe2O3 is less than 0.2%.

In cement industry, the addition of fluorite as mineralizer can reduce sintering temperature and fuel consumption, increase the liquid viscosity of clinker and promote the formation of tricalcium silicate. In cement production, the amount of fluorite is between 0.8% and 5%. Although the quality requirement of fluorite in cement industry is not strict, the general CaF2 content can be more than 40%, and the impurity content is not specified.

In ceramic industry, fluorite is mainly used as porcelain glaze, which can help color and melt in the production process of porcelain glaze. The amount of fluorite added in the production of porcelain glaze is about 10 to 20 percent. Fluorite is also used in enamel industry and cast stone production, the addition amount is 3-10% and 3% respectively.

In refractory industry, fluorite powder as a mineralizer, especially in the production of siliceous refractory brick, adding a certain proportion of fluorite powder can effectively reduce the surface cracks of products, eliminate the appearance defects, and improve the yield of finished products.

SPECIFICATION :

| Fluorite | ||||

| Item | Chemical Content,% | |||

| CaF2 , > | SiO2, < | S, < | P, < | |

| FL-98 | 98 | 1.5 | 0.05 | 0.03 |

| FL-97 | 97 | 2.5 | 0.05 | 0.05 |

| FL-95 | 95 | 4.5 | 0.1 | 0.06 |

| FL-90 | 90 | 9.0 | 0.1 | 0.06 |

| FL-85 | 85 | 14 | 0.15 | 0.08 |

| FL-80 | 80 | 18 | 0.2 | 0.08 |

| FL-75 | 75 | 23 | 0.2 | 0.08 |

| FL-70 | 70 | 28 | 0.25 | 0.08 |

| FL-65 | 65 | 32 | 0.3 | 0.08 |

At present, fluorite has become a resource that all countries are protecting. In accordance with the requirements of China's import and export administration, our company already has the qualifications to go through the relevant export licensing procedures. Can provide you with appropriate fluorite products, welcome to consult and negotiate.

Leave a message: Please fill in your information and we will contact you soon.