- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

Deoxidizer

Description

Controls aluminum is the most widely used deoxidizer in steelmaking at present. Aluminum and oxygen have strong affinity, high deoxidation efficiency and low cost. When aluminum is deoxidized, the total oxygen content in steel is very low, and the oxide inclusions formed are easily floating and removed. It can also be more economical to produce fine grain steel. According to the shape, can be divided into aluminum wire, aluminum particles, aluminum blocks, aluminum powder.

1. Aluminum wire.

Aluminum wire is the most commonly used deoxidizer in modern steelmaking and production. The main functions of the aluminum wire in the steel are as follows: it can stabilize the liquid steel and prevent the bubble formation during the solidification of the liquid steel, form the dispersed AlN particles, fix the nitrogen in the steel, control the austenite grain size of the steel when it is reheated, and raise the grain coarsening temperature. It can reduce the overheating sensitivity and hardenability of the steel, improve the weldability of the steel, restrain the aging characteristic of the low carbon steel, reduce the notch sensitivity and ductile transition temperature of the steel, etc.

1.1. Specification Type: Diameter 9.5-13mm; Model: L, L2, L4,L6.

1.2. Quality standards: Round appearance, uniform size, clean surface, no fold, wrong circle, cracks, inclusions, kink and other harmful defects.

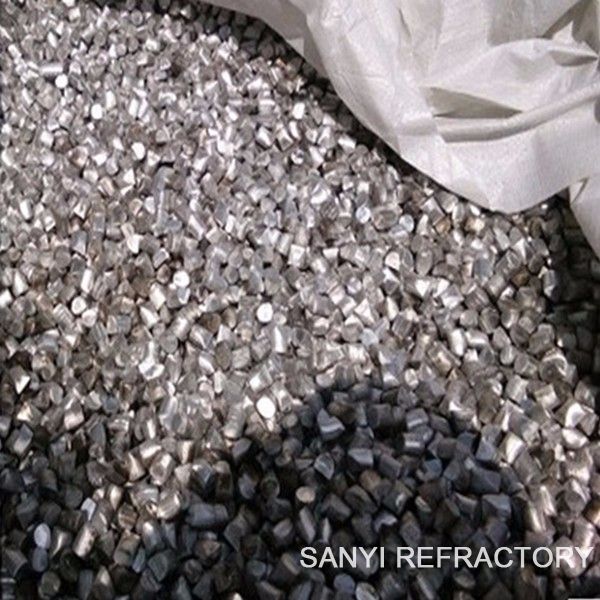

2. Aluminum Particle/Block.

The surface of the product should be smooth without burrs, slag inclusion and serious pores; specifications, shape, weight according to customer requirements. Product Characteristics as follows:

2.1. High globality, low impurity content, active aluminum accounting for more than 98%. 2.2. Silver gray appearance, no foreign inclusions and agglomerations, very low moisture content, can be stored for a long time.

2.3. The product size is uniform and the distribution range is narrow.

2.4. The vibrating density is high.

3. Aluminum Powder.

The addition of metal aluminum powder as additive into carbon-containing refractory products (magnesia carbon brick, aluminum magnesia carbon brick) will greatly improve the oxidation resistance of the product and further improve its service life, while the content of active aluminum and the median diameter D50 are the most important factors. The higher the content of active aluminum, the higher the oxidation resistance of the product, the smaller the median diameter, the more uniform the distribution, the larger the contact area between aluminum powder and other elements (that is, the larger the specific surface area), the better the oxidation resistance of the product.

3.1. Product Characteristics as follows:3.1.1. Uniform particle size, narrow distribution interval, high density of vibration.

3.1.2. High globality, low impurity content, active aluminum above 98%.

3.1.3. The appearance is silver gray, no foreign inclusions and agglomerations, very low moisture content, can be stored for a long time.

3.2. Application Scope:

3.2.1. Uniform particle size, narrow distribution interval, high density of vibration.

3.2.2. High globality, low impurity content, active aluminum above 98%.

3.2.3. The appearance is silver gray, no foreign inclusions and agglomerations, very low moisture content, can be stored for a long time.

3.2.4. Aerospace (solid rocket propellant).

3.2.5. Chemical industry (various chemical catalysts), Pesticide).

3.2.6. Metallurgical (aluminothermic metallurgy, steelmaking deoxidizer).

3.2.7. Refractory (steel-making aluminum-magnesia carbon brick).

3.2.8. New building materials (aerated concrete gassing agent).

3.2.9. Anticorrosive material.

3.2.10. Fireworks and firecrackers, etc.

Description of Aluminum Deoxidizer Products:

1. Product application and fire source, heat source, water, acid, alkali, oxidant and corrosion isolation.

2. Packing should be sealed at all times.

3. To be transported by caravan. When unloading, do not throw, bump, inverted.

4. Store in a dry, ventilated warehouse with windows not less than 1 m away from heating.

Leave a message: Please fill in your information and we will contact you soon.