- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

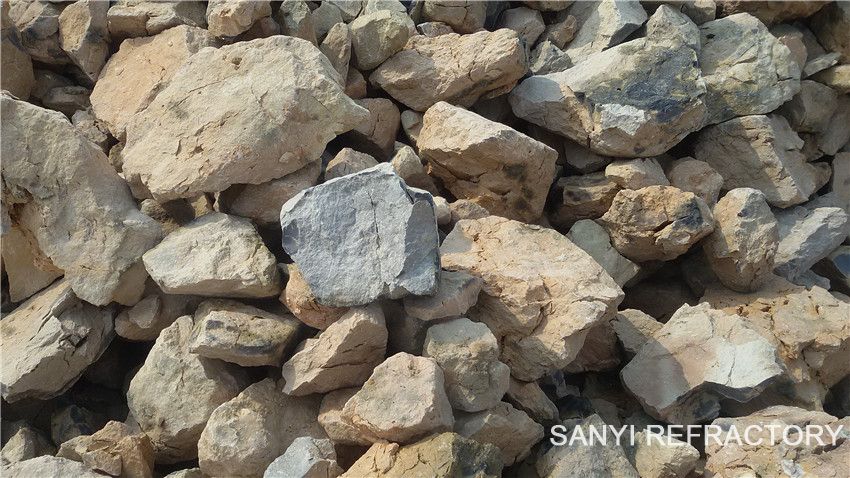

Calcined Bauxite

Description

The main firing equipment for bauxite clinker products are rotary kiln, shaft kiln, shuttle kiln and down draught kiln ,Because of the different structure and operation mode of each kiln, the firing temperature and physicochemical index of the products are different, which respectively meet different industrial uses.

Normally, bauxite is calcined at a high temperature of 1400 to 1600 degrees in the kiln, and at a temperature higher than the temperature of the secondary mullite phase transformation, resulting in the formation of the mullite corundum phase with higher purity and density, with good thermal shock resistance and other superior physical and chemical properties, widely used in aluminum smelting, metallurgy, chemical, refractories and other industries. the calcined bauxite clinker has been tested and classified into different grades according to the content of alumina, then through the crushing system, processing into particles and fine powder to meet the actual needs of different customers.

At present, our calcined bauxite clinker products have been sold all over the world, relying on China's high-quality aluminum ore resources, advanced production technology, scientific management system, quality and cheap products and thoughtful service. Has been recognized by the vast number of customers, welcome to consult and negotiate at any time, we will achieve your satisfaction with high quality products and services.

Normally, bauxite is calcined at a high temperature of 1400 to 1600 degrees in the kiln, and at a temperature higher than the temperature of the secondary mullite phase transformation, resulting in the formation of the mullite corundum phase with higher purity and density, with good thermal shock resistance and other superior physical and chemical properties, widely used in aluminum smelting, metallurgy, chemical, refractories and other industries. the calcined bauxite clinker has been tested and classified into different grades according to the content of alumina, then through the crushing system, processing into particles and fine powder to meet the actual needs of different customers.

At present, our calcined bauxite clinker products have been sold all over the world, relying on China's high-quality aluminum ore resources, advanced production technology, scientific management system, quality and cheap products and thoughtful service. Has been recognized by the vast number of customers, welcome to consult and negotiate at any time, we will achieve your satisfaction with high quality products and services.

| Shaft Kiln Bauxite | |||||

| Item | GAL-70 | GAL-80 | GAL-85 | GAL-88 | |

| Chemical Content,% | Al2O3,≥% | 70 | 80 | 85 | 88 |

| Fe2O3,≤% | 2.2 | 2.0 | 1.8 | 1.6 | |

| TiO2,≤% | 4 | 4 | 4 | 4 | |

| CaO+MgO,≤% | 0.6 | 0.5 | 0.4 | 0.4 | |

| R2O,≤% | 0.7 | 0.6 | 0.4 | 0.4 | |

| Physical Properties | B.D ≥g/cm3 | 2.5 | 2.7 | 3.1 | 3.2 |

| W.A,≤% | 6 | 5 | 4 | 4 | |

Size Available:

Sized Sand: 0-1mm,1-3mm, 3-5 mm, 5-8mm, 8-12mm

Fine Powder: 100mesh,180mesh, 240mesh, 320mesh

In addition to the above dimensions, we can also process according to your requirements.

Leave a message: Please fill in your information and we will contact you soon.