- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

Resistance Furnace

Description

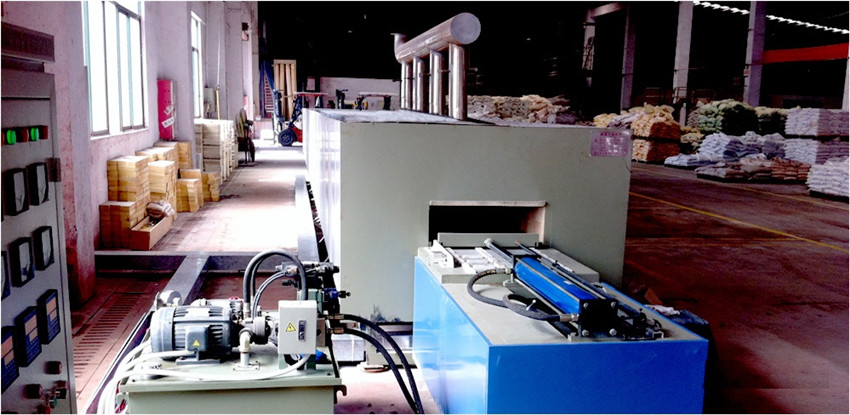

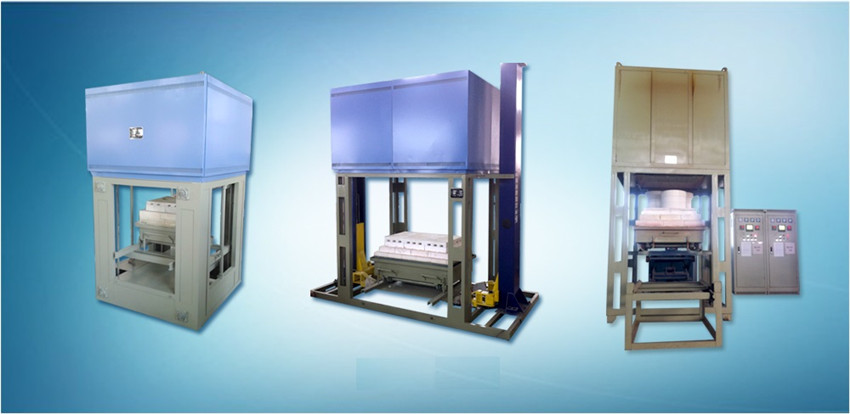

According to the different structure, this series of alumina ceramic sintered push plate resistance furnace can be divided into two types: single hole pushing kiln and double hole pushing plate kiln.

1.Alumina Ceramic Sintering Pusher Kiln (Single hole)

The single hole push plate kiln is a continuous working furnace with silicon molybdenum rod as heating element and the highest working temperature at 1750 ℃. It belongs to a continuous working energy saving kiln. It can be selected according to different products. It is mainly applicable to high temperature sintering of zirconia ceramic knives, alumina ceramics and zirconia structural ceramics.

Structural characteristics :

The furnace is mainly divided into three sections: preheating zone, high temperature zone and cooling zone. The furnace body is divided into sections, and the heating element is U type silicon molybdenum rod, which distributes evenly on both sides of the furnace.

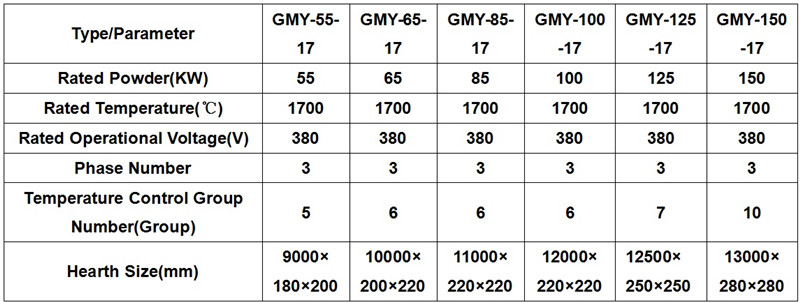

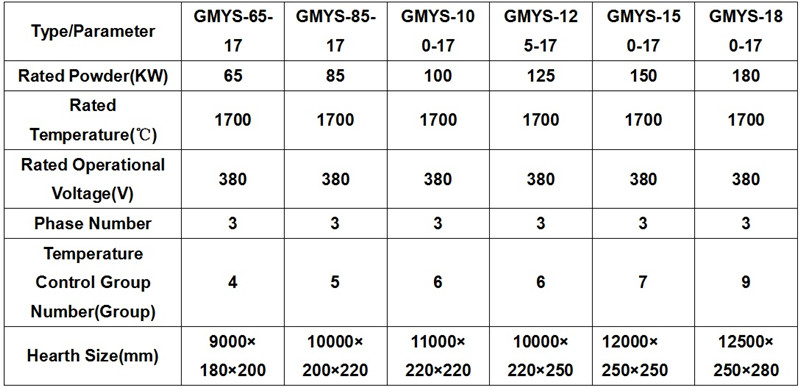

The main technical parameters are as follows:

1.Alumina Ceramic Sintering Pusher Kiln (Single hole)

The single hole push plate kiln is a continuous working furnace with silicon molybdenum rod as heating element and the highest working temperature at 1750 ℃. It belongs to a continuous working energy saving kiln. It can be selected according to different products. It is mainly applicable to high temperature sintering of zirconia ceramic knives, alumina ceramics and zirconia structural ceramics.

Structural characteristics :

The furnace is mainly divided into three sections: preheating zone, high temperature zone and cooling zone. The furnace body is divided into sections, and the heating element is U type silicon molybdenum rod, which distributes evenly on both sides of the furnace.

The main technical parameters are as follows:

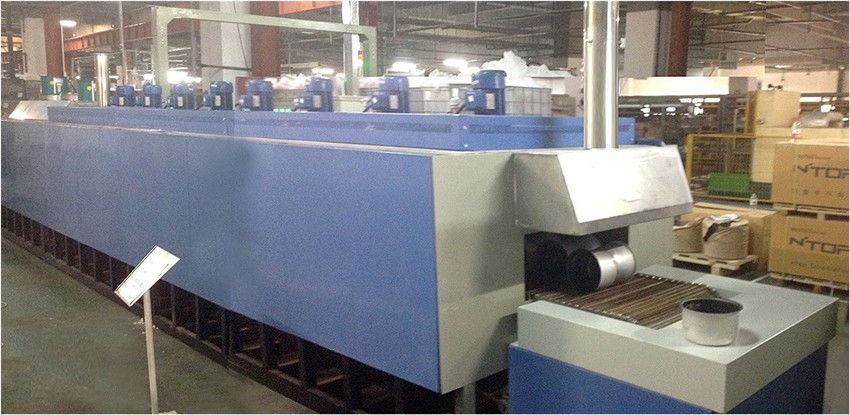

2. Alumina Ceramic Sintering Pusher Kiln(double hole)

The two-hole push-plate tunnel kiln is a kind of continuous working type, which is mainly two kinds of double-hole codirectional propulsion and two-hole reverse propulsion. The silicon molybdenum rod is used as heating element, and the maximum working temperature is 1750 ℃. it can be used according to different products, mainly used for alumina ceramic substrate, zirconia structure ceramics, electronic ceramics, honeycomb ceramics, rare earth oxides, fluorescent materials, magnetic materials for high temperature burning.

Structural characteristics :

The product is divided into two series of forward propulsion and reverse propulsion, the pushing plates of the two firepots are continuously pushed in reverse direction and in the same direction when working.The design is divided into preheating zone, high temperature area and cooling zone.The reverse propulsion furnace material internal circulation, reduce heat loss.The preheating zone absorbs the residual heat from the cooling area and makes full use of the heat energy, and the energy saving effect is remarkable. Compared with single hole kiln, it has many advantages, such as low investment, large production, small floor area, low labor consumption and high efficiency.According to the actual calculation, the unit power consumption of the double hole kiln is only 70% of that of the single hole kiln.The benefits of enterprises are obvious. It is an ideal sintering equipment for large-scale production in enterprises.

The main technical parameters are as follows:

Leave a message: Please fill in your information and we will contact you soon.