- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

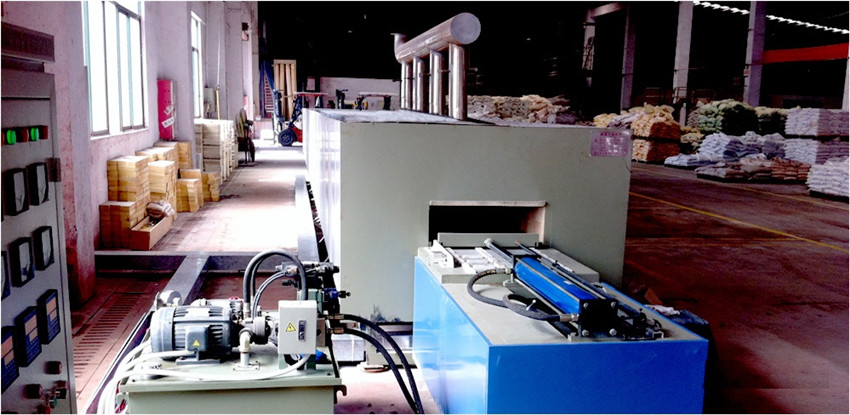

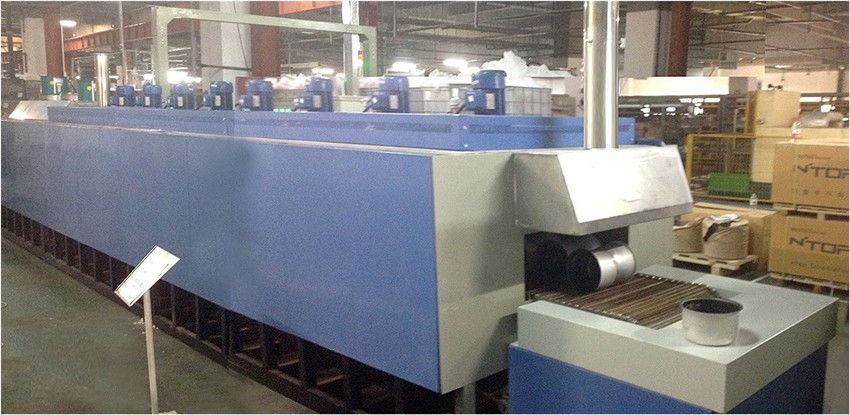

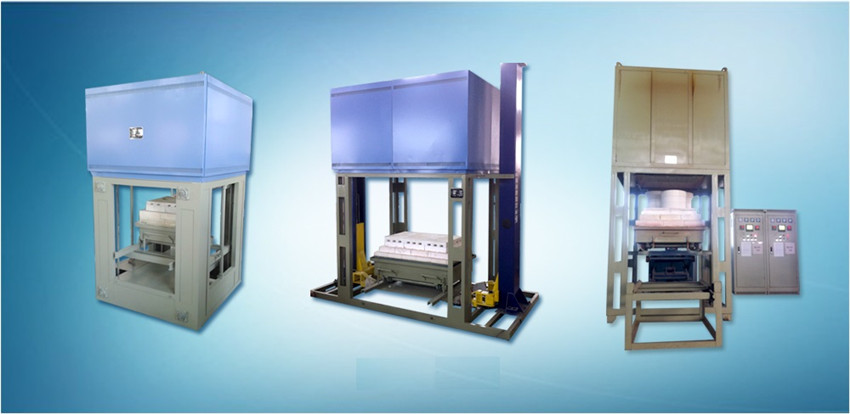

Resistance Furnace

Description

This series of push plate type tunnel kiln is continuous operation type, with silicon carbon rod and resistance wire as heating element, the maximum working temperature is 1000 ℃.There are two kinds of single-hole kiln and Double-hole kiln.Kiln for continuous operation, stable temperature curve. The inlet tuyere is arranged at the bottom of the furnace, the air volume can be adjusted, the material can be oxidized and calcined, and the product consistency is good.The upper and lower layers set the heating temperature measuring point, the middle setting temperature measuring point, the furnace temperature uniformity is good, the pushing board material uses corundum mullite, very durable.This series of push-plate tunnel kiln is widely used in high temperature calcination of zirconia powder, lithium cobalt oxide and oxalic acid.

Technical Parameters:

Technical Parameters:

| Type/Parameter | GTY-120- 10 |

GTY-200- 10 |

GTY230- 10 |

GTY-250- 10 |

GTY-250- 10 |

| Rated Powder(KW) | 120 | 200 | 230 | 250 | 250 |

| Rated Temperature(℃) | 1000 | 1000 | 1000 | 1000 | 1000 |

| Rated Operational Voltage(V) | 380 | 380 | 380 | 380 | 380 |

| Phase Number | 3 | 3 | 3 | 3 | 3 |

| Temperature Control Group Number(Group) | 11 | 17 | 20 | 9 | 17 |

| Hearth Size(mm) | 12000× 570×200 |

17000× 570×200 |

20000× 570×200 |

14000× 900×280 |

20000× 570×250 |

| Application | Lithium Cobalt Oxide | Lithium Cobalt Oxide | Lithium Cobalt Oxide | Cobalt Oxalate | Lithium Cobalt Oxide |

Leave a message: Please fill in your information and we will contact you soon.