- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

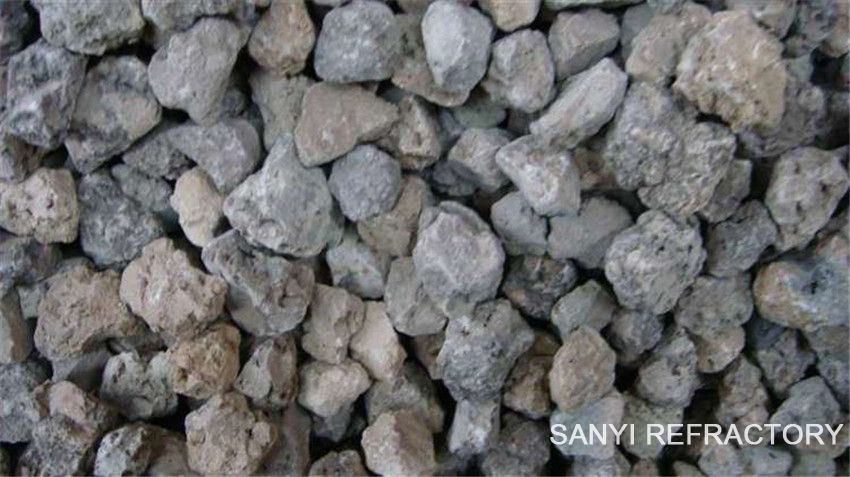

Premelted Refining Slag

Description

Our premelted slag products include fused calcium aluminate, fused calcium silicate and calcium ferrate. Mainly used in iron and steel metallurgy and out of furnace refining,Due to its uniform composition, low melting point, fast melting speed, deoxidization and desulfurization, slagging submerged arc, removal of inclusions and so on, the smelting efficiency and quality can be greatly improved, and it is an ideal metallurgical auxiliary material. By domestic and foreign metallurgical industry customer attention and recognition.Considering the difference of steel smelting by customers, our company not only provides premelted refining slag products with existing specifications and indexes, but also customizes products of various specifications and indexes according to customers' requirements. Welcome to know and negotiate, we will achieve your satisfaction with quality service.

Calcium ferrate, also known as premelting slag making agent, provides the best slag forming conditions for steelmaking process, and it can quickly degrade slag and shorten the smelting period. Because of the improvement of slagging condition, the use efficiency of lime is improved, so it is not necessary to use fluorite to aid melting, and it can save lime consumption, at the same time, it can realize good dephosphorization effect and improve the quality of molten steel.

The characteristics of calcium ferrate as premelted refining slag are as follows:

1.The speed of slag formation is fast.As a result of premelting, a mixture with low melting point has been formed, which is added to the furnace to form a liquid state rapidly, realizing the purpose of slagging in the early stage of smelting.After the liquid slag is formed by adding the premelted slag making agent (calcium ferrate), the contact surface of the added active lime in the liquid slag becomes larger, and it is easy to dissolve.At the same time, the high ferric oxide in the premelted slag making agent (calcium ferrate) can rapidly reduce the melting point of calcium oxide and promote the rapid dissolution of lime.

2.Because of the good slagging, good dephosphorization conditions were created in the furnace.The dephosphorization rate can be increased by 3% and 5% respectively.

3.The final carbon content and melting pool temperature are higher than the average value after the use of premelted slag, which indicates that the heat recovery rate is increased and the molten steel will not be oxidized too much, which is beneficial to improve the quality of steel.

4.The premelted slag making agent (calcium ferrate) can accelerate the dissolution of lime, so it is unnecessary to use fluorite to aid melting, and the furnace lining erosion is reduced and the environmental pollution is reduced.

5.Due to good slagging, smooth smelting and reducing the spatter of molten steel, the yield of liquid steel can be increased by about 1%.

6.The smelting period is shortened. Rapid slagging and high-efficiency dephosphorization can shorten the smelting time.

The Specification As Follows:

Calcium ferrate, also known as premelting slag making agent, provides the best slag forming conditions for steelmaking process, and it can quickly degrade slag and shorten the smelting period. Because of the improvement of slagging condition, the use efficiency of lime is improved, so it is not necessary to use fluorite to aid melting, and it can save lime consumption, at the same time, it can realize good dephosphorization effect and improve the quality of molten steel.

The characteristics of calcium ferrate as premelted refining slag are as follows:

1.The speed of slag formation is fast.As a result of premelting, a mixture with low melting point has been formed, which is added to the furnace to form a liquid state rapidly, realizing the purpose of slagging in the early stage of smelting.After the liquid slag is formed by adding the premelted slag making agent (calcium ferrate), the contact surface of the added active lime in the liquid slag becomes larger, and it is easy to dissolve.At the same time, the high ferric oxide in the premelted slag making agent (calcium ferrate) can rapidly reduce the melting point of calcium oxide and promote the rapid dissolution of lime.

2.Because of the good slagging, good dephosphorization conditions were created in the furnace.The dephosphorization rate can be increased by 3% and 5% respectively.

3.The final carbon content and melting pool temperature are higher than the average value after the use of premelted slag, which indicates that the heat recovery rate is increased and the molten steel will not be oxidized too much, which is beneficial to improve the quality of steel.

4.The premelted slag making agent (calcium ferrate) can accelerate the dissolution of lime, so it is unnecessary to use fluorite to aid melting, and the furnace lining erosion is reduced and the environmental pollution is reduced.

5.Due to good slagging, smooth smelting and reducing the spatter of molten steel, the yield of liquid steel can be increased by about 1%.

6.The smelting period is shortened. Rapid slagging and high-efficiency dephosphorization can shorten the smelting time.

The Specification As Follows:

| Calcium Ferrate | |||

| Item | CF-1 | CF-2 | CF-3 |

| CaO | 48-55 | 34-39 | 35-47 |

| Fe2O3, ≤ | 30-43 | 53-63 | 44-63 |

| Al2O3 | 1.0-5.5 | 0.9 | 4-5.2 |

| SiO2 | 5 | 2.15 | 1.71 |

| MgO, | 2 | 2 | 2 |

| p, < | 0.05 | 0.05 | 0.05 |

| S,< | 0.05 | 0.05 | 0.05 |

| MP, ℃ | 1100-1250 | ||

Size Available:

Sized Sand: 0-50mm

Packing Method:Ton bag packing

In addition to the above dimensions, we can also process according to your requirements.

Leave a message: Please fill in your information and we will contact you soon.