- Refractory Raw Materials

Calcined Bauxite Ceramic Foundry Sand Corundum Flint Clay Fluorite Mulite Silica Fume Silicon Carbide Silicon Metal Alpha Alumina Powder Spinel Alumina Bubble Aluminum Powder Bentonite Boron Carbide Ceramic Sand Chromium Oxide Green Cordierite Explosion-proof Fiber Forsterite Fused Silica Graphite High Alumina Cement Kyanite Group Minerals Potassium Feldspar Powdery Instant Sodium Silicate Pure Calcium Aluminate Cement Spherical Asphalt White Clay Zirconite Lignin Synthesis of Ferro Silicon Nitride Homogenized Bauxite

- Refractory Products

- Monolithic Refractories

- Ceramic Fiber Products

- Metallurgical Auxiliary Material

- Industrial Kilns And Parts

Ceramic Fiber Blanket

Description

Ceramic fiber blanket is made of aluminum silicate fiber filament by special double-sided needling process. The interweaving degree,anti stratification performance, tensile strength and surface evenness of the fibers were greatly improved after double-sided acupuncture. It does not contain any organic bond to ensure that it has good makeability and stability under high temperature and low temperature.

Ceramic Fibre Blankets Have The Following Characteristics:

1. The color is white, the size is regular, has the fire resistance, the heat insulation, the insulation performance. No binding agent, Good tensile strength, toughness and fiber structure can be maintained in neutral and oxidized atmosphere. The temperature tolerance range is 950-1400 ℃.

2. Excellent chemical stability, thermal stability; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

3. Widely used, involving many industries. It can be used for high temperature insulation heat insulation for aerospace, steel, petrochemical, fire insulation of military equipment, industrial kiln, wall lining of heating device, insulation insulation of back lining, insulation and insulation of high temperature equipment, insulation and insulation of high temperature pipeline, heat insulation and fire protection of electrical components; high temperature gasket; module, folding block material and so on. Such as electric power boiler, gas turbine and nuclear power insulation, chemical industry high temperature reaction equipment and heating equipment wall lining, high-rise building fire insulation, furnace door and top heat insulation, high temperature filtration materials and other industrial equipment.

Ceramic Fibre Blankets Have The Following Characteristics:

1. The color is white, the size is regular, has the fire resistance, the heat insulation, the insulation performance. No binding agent, Good tensile strength, toughness and fiber structure can be maintained in neutral and oxidized atmosphere. The temperature tolerance range is 950-1400 ℃.

2. Excellent chemical stability, thermal stability; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

3. Widely used, involving many industries. It can be used for high temperature insulation heat insulation for aerospace, steel, petrochemical, fire insulation of military equipment, industrial kiln, wall lining of heating device, insulation insulation of back lining, insulation and insulation of high temperature equipment, insulation and insulation of high temperature pipeline, heat insulation and fire protection of electrical components; high temperature gasket; module, folding block material and so on. Such as electric power boiler, gas turbine and nuclear power insulation, chemical industry high temperature reaction equipment and heating equipment wall lining, high-rise building fire insulation, furnace door and top heat insulation, high temperature filtration materials and other industrial equipment.

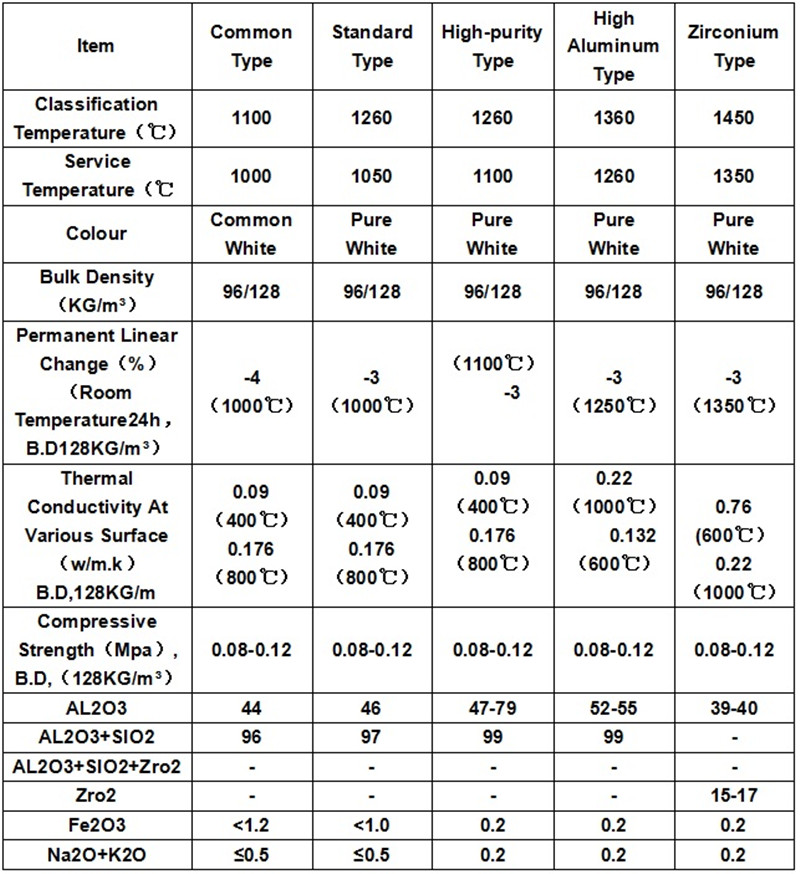

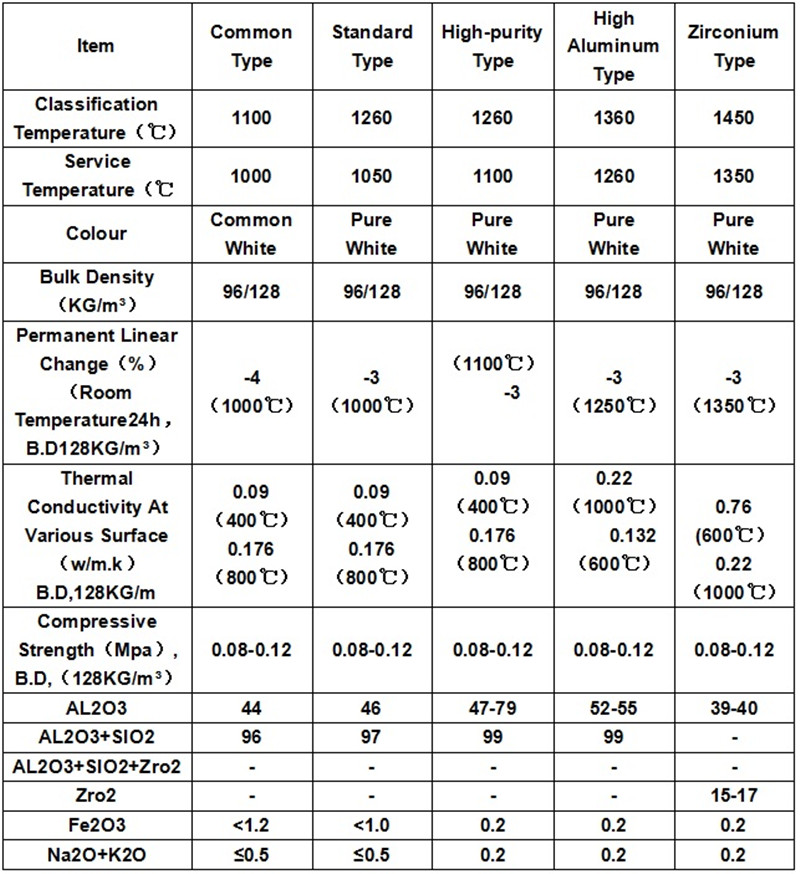

Technical Parameters Of Ceramic Fiber Blanket Are As Follows:

Size(mm):

Common Specification:

15000x610/1220x10mm,

14400x610/1220x12.5mm,

7200x610/1220x20mm,

7200x610x1220x25mm,

5000x610/1220x30mm,

4500x610/1220x40mm,

3600x610/1220x50mm

In addition to above Specifications, We can also customize processing according to your requirements.

Leave a message: Please fill in your information and we will contact you soon.